Special wishes? Of course!

Lohmann manufactures special sliding bearings according to your wishes. We adapt the sliding bearing to your requirements and to the possibilities of our machinery in operation. This is how we create the optimal solution to your application. Our machinery in operation comprises 2 milling machines, 4 lathes and one plate bending machine.

Manufactured with high precision

We design with SolidWorks® CAD software, and CNC manufacturing is done on state-of-the-art turning- and milling machines. So you will get exactly what you need.

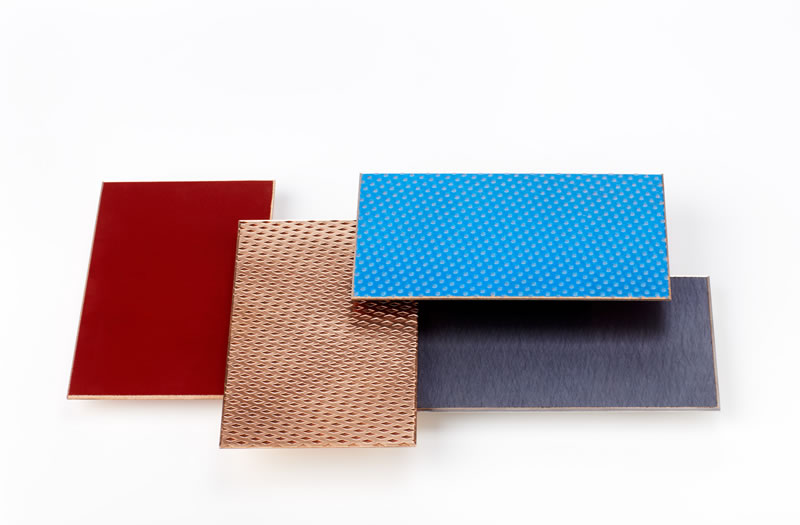

Roller-burnished metal sheets

We manufacture roller-burnished sliding bearings in accordance with DIN ISO 3547. We can manufacture any intermediate size with diameters between 100 mm and 600 mm. In general, the basic material is a 2.5-mm-thick metal sheet for composite bearings. We also manufacture other roller-burnished products made of CuSn8 at our customers’ request.

Manufacturing process

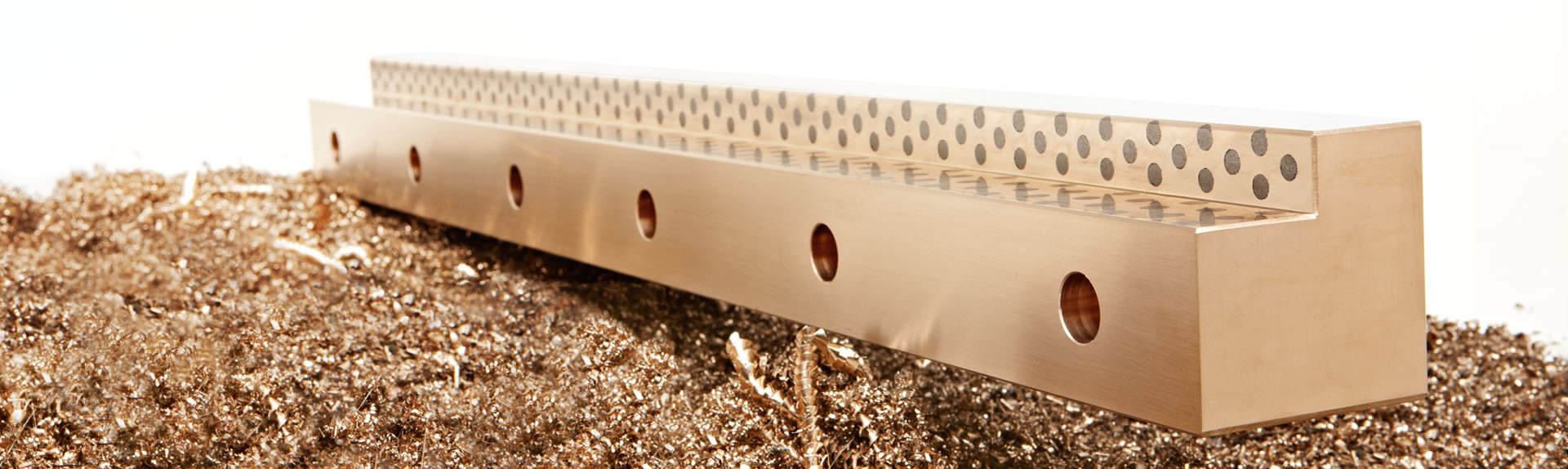

Shortening

There are many applications in which standard sliding bearings cannot be used, because catalogue items would not fit. Lohmann shortens and cuts the standard sliding bearings to the desired lengths.

Manufacturing process

Roller-burnishing

The roller-burnishing of sliding bearing bushings has the advantage that there are hardly any limits with regard to the diameters and lengths of the bushings. In general, Lohmann processes material with a wall thickness of 2.5 mm; other wall thicknesses are also available. Lohmann can manufacture any desired size with diameters between 100 mm and 600 mm.

Manufacturing process

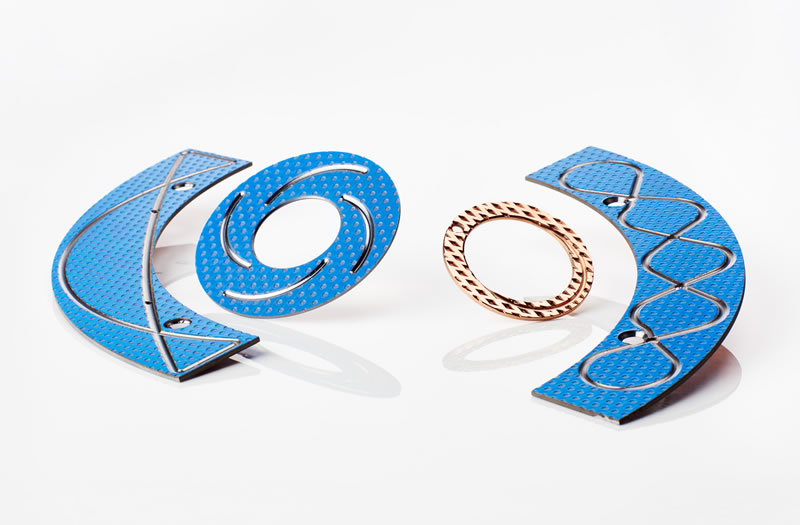

Water-jet cutting & machining

Other than the roller burnishing and shortening of sliding bearings, we also use different other manufacturing possibilities. Thanks to our state-of-the-art turning- and milling machines we can finish any sliding element to customer’s specifications by notching lubrication grooves and by drilling holes and counterbores. Likewise, critical parts are water-jet cut.