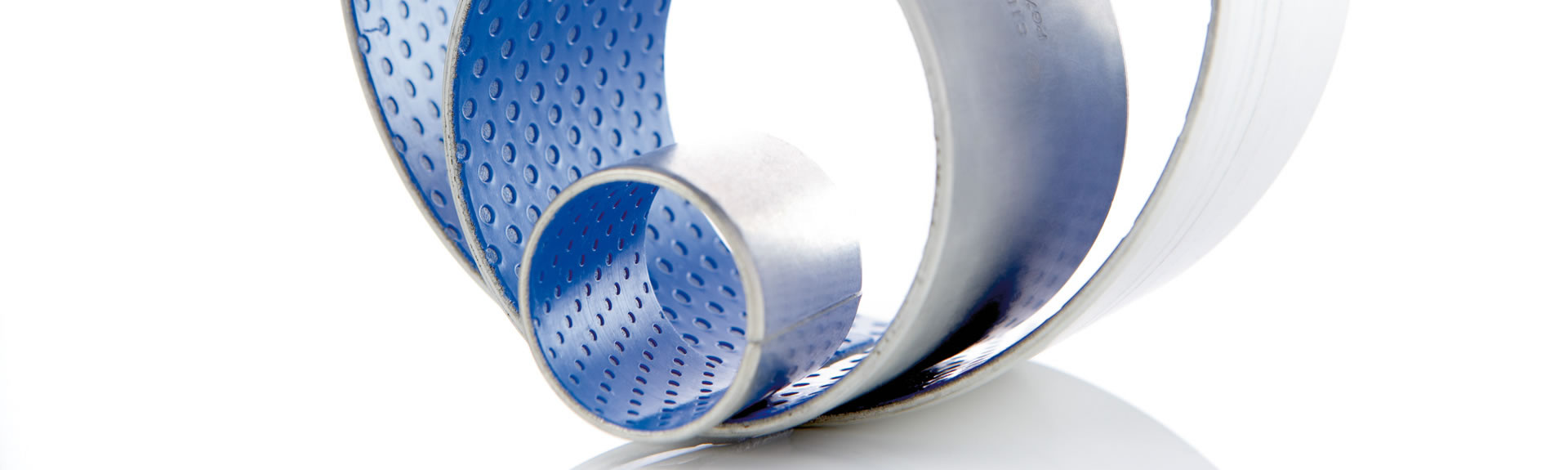

Wrapped dry sliding bearings

GLYCODUR wrapped dry sliding bearings Glyco F/A and RB/RS

GLYCODUR® dry sliding bearings are available as a catalogue commodity in two standard versions, GLYCODUR® F and GLYCODUR® A. Both versions have different sliding layers according to ISO 3547 type P1 and P2.

GLYCODUR® RB and GLYCODUR® RS complement the proven lead-free GLYCODUR® sliding bearings with an important new characteristic: they are corrosion-resistant!

Whereas the GLYCODUR® sliding bearings have a copper-plated steel backing (see also: GLYCODUR® sliding bearing catalogue), the GLYCODUR® RB and GLYCODUR® RS use different backing materials.

The original for automotive and industrial applications

ISO 3547/DIN 1494 steel-bronze-PTFE composite

Eco-friendly, lead-free, RoHS-compliant

GLYCODUR® F

GLYCODUR® F sliding bearings have a steel base, to which a 0.2 to 0.4 mm porous tin bronze layer is sintered. The pores of this layer are filled during a rolling process with polytetrafluoroethylene (PTFE) and other friction- and wear-reducing additives. A 5 to 30 μm top layer made of the same material forms the running-in layer. GLYCODUR® F sliding bearings combine in optimal manner the mechanical properties of the sintered bronze with the sliding and lubrication properties of a PTFE mixture. The structure of this composite material results in good dimensional stability and good thermal conductivity.

GLYCODUR® A

GLYCODUR® A sliding bearings have a steel base and a 0.2 to 0.4 mm sintered tin bronze layer. The principal characteristic of these bearings is the polyoxymethylene (POM) top layer, which is solidly joined to the sintered bronze. The surface layer, which is 0.3 mm thick, features pockets for lubrication grease. GLYCODUR® A dry sliding bearings are therefore to some extent unaffected by misalignments, including related edge loads.

GLYCODUR® AB

GLYCODUR® AB sliding bearings have a similar composition to GLYCODUR® A sliding bearings, but they have a 0.35 mm top layer made of POM. This allows the final machining of the sliding surface on installed bushings by boring or turning, or in exceptional cases by reaming to adjust possible misalignments or to achieve small operating clearance.

GLYCODUR® RB

GLYCODUR® RB sliding bearings have a bronze backing which makes them corrosion-resistant. At the same time, they have particularly good heat conductivity compared to GLYCODUR® F sliding bearings. If heat is generated by the application, it can be dissipated better through the bearing into the housing.

GLYCODUR® RS

GLYCODUR® RS sliding bearings have a stainless-steel backing that is very corrosion resistant. They are suitable for all applications where it is important to avoid corrosion (the food industry for instance).